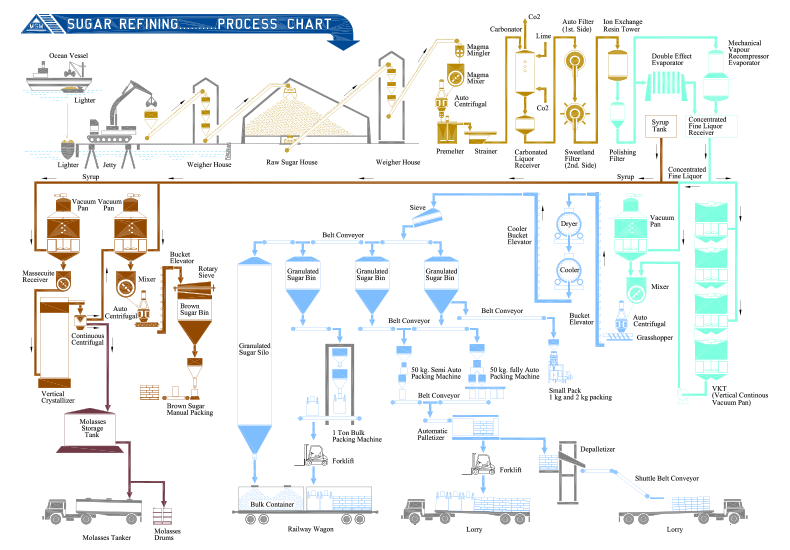

The major stages of MSM Prai's refining operations is described below.

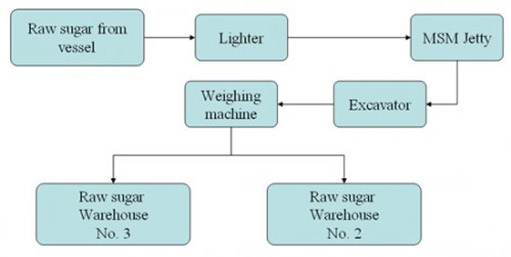

Raw sugar delivered by ocean vessels is transferred to lighters and brought to MSM jetty. A crane and excavator equipped with grab buckets are used to unload raw sugar from the lighters onto belt conveyors. The conveyors transport the sugar to a weigher for weighing before unloading the sugar in the warehouse for storage.

Kindly refer diagram below.

Typically, the raw sugar unloading capacity averages around 7000 to 8000 tonnes per day. Our two warehouses have a combined capacity of 90,000 metric tonnes. Below is the breakdown:

- No 2 Raw Sugar Warehouse Capacity : 25,000 metric ton

- No 3 Raw Sugar Warehouse Capacity : 65,000 metric ton

In the first step of refining operation, raw sugar crystals are mixed with raw syrup to soften and remove the crystal outer coatings of impurities. The crystals are then separated from the syrup and hosed with hot water in a centrifuge. This process is called “affination”.

The washed sugar discharged from the centrifuge is dissolved in a premelter to form melted liquor. The melted liquor is pumped to the carbonator where lime and carbon dioxide are added to form a precipitate of calcium carbonate which traps most of the impurities.

The carbonated precipitate together with the impurities are removed by pressure filtering through the first and second side filters leaving behind “clear liquor”.

Filtration station consists of the followings:

- First stage filtration: Rotary drum filters

- Second stage filtration: Sweetland filters

- Polishing filtration: Sweetland filters

Further colour removal is achieved by pumping the clear liquor through towers containing ion exchange resins (IER). The colour-causing components in the liquor are adsorbed onto the resin surfaces and left-behind.

To ensure that no solid impurities get carried forward in the process, the “decoloured liquor” undergoes a final filtration stage in the polishing filters.

Falling Film Evaporator

Double Effect Evaporator

The treated liquor, now called “fine liquor” is ready for crystallisation. However, it must first be concentrated by having its excess water content removed.

Two different sets of equipment are used for this purpose:

- A falling film evaporator using as its heat source vapour supplied by a mechanical vapour re-compressor (MVR)

- A double effect plate evaporator (DEPE)

The concentrated fine liquor leaving the evaporators is subsequently boiled in a vessel known as a vacuum pan to form sugar crystals. Fine sugar crystals are used as “seed”. The crystals are grown to the required size by adding more liquor. When they are large enough, the mixture of sugar crystal and syrup is formed - called “massecuite” and is discharged from the pan.

Vacuum Pan

- Refined Pans (white sugar): Batch Pan, Vertical Crystallisation Tower (VKT)

- Recovery Pans (brown sugar): Batch Pan and Vertical Crystallizer

The massecuite undergoes separation into its component crystal and syrup constituents in a centrifuge machine. In the machine the crystals are hosed with hot water to enhance the separation effect.

Dryer

Cooled

Sieved

The refined sugar crystals are then dried, cooled, sieved and stored in storage bins.

From the storage bins, the sugar is transported by conveyor belts to the packaging area and packed into various grades or transferred into the silo for sugar delivery by bulk containers.